Volatile Organic Compounds (VOCs) are harmful airborne pollutants commonly released during industrial processes such as painting, printing, chemical handling, and material treatment. These compounds can pose serious health risks and significantly degrade indoor air quality if not properly controlled.

This article examines how activated carbon filters are used to effectively capture and remove VOCs from the air. It also outlines key performance standards for industrial air purification systems and provides guidance on selecting filtration technologies that ensure regulatory compliance and operational safety.

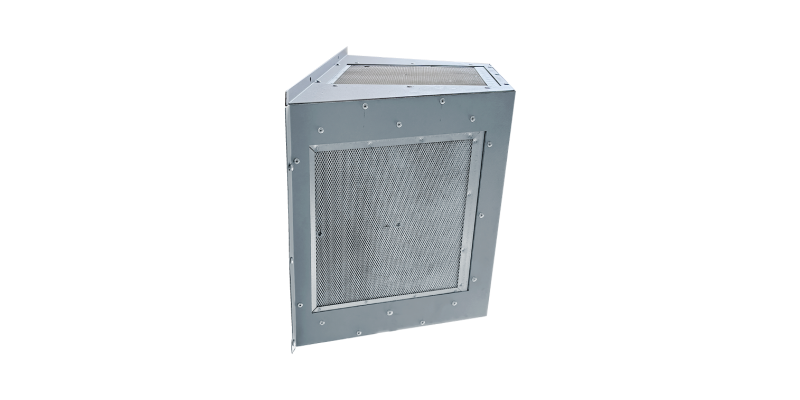

A VOC air filter designed for industrial environments must be capable of removing gaseous contaminants with high efficiency. Unlike particulate filters, VOC filtration requires adsorption rather than mechanical separation. Activated carbon is the most widely used medium for this purpose due to its highly porous structure and large internal surface area, which allow it to bind volatile organic compounds at the molecular level.

An activated carbon filter for VOC removal works by adsorbing organic vapors as contaminated air passes through the carbon bed. The effectiveness of this process depends on several factors, including carbon type, impregnation, residence time, air velocity, and VOC concentration. For industrial applications, customized carbon blends are often required to target specific compounds such as solvents, hydrocarbons, aldehydes, or ketones.

An industrial VOC air purifier typically integrates activated carbon filters with pre-filtration stages. Pre-filters remove particulate matter that could clog the carbon media and reduce adsorption efficiency. In some systems, HEPA filters are added to control fine particles alongside gaseous pollutants, ensuring comprehensive air treatment.

Performance standards play a critical role in evaluating air purifiers for volatile organic compounds. International guidelines such as ISO 10121 define test methods for gas-phase air cleaning devices, focusing on adsorption capacity, efficiency, and breakthrough time. Compliance with occupational exposure limits (OELs) and indoor air quality regulations is essential for industrial operators, particularly in sectors handling hazardous chemicals.

When selecting a VOC air filtration system, several criteria should be considered: the specific VOCs present, airflow requirements, system pressure drop, filter lifespan, and maintenance intervals. Proper system sizing and routine monitoring are necessary to ensure consistent performance and to prevent filter saturation, which can lead to VOC re-emission.

In conclusion, activated carbon-based VOC air filters represent a proven and effective solution for controlling volatile organic compounds in industrial environments. When combined with appropriate performance standards and system design, these technologies support safer workplaces, regulatory compliance, and improved air quality.

Deutsch

Deutsch Francais

Francais Italiano

Italiano